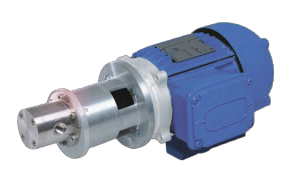

Mag Drive Gear Pumps

AxFlow UK offers three ranges of magnetically driven gear pumps.

Mag drive gear pumps (magnetically driven gear pumps) are sealless positive displacement pumps that combine the accurate, repeatable flow of a gear pump with the containment benefits of a magnetic coupling. Instead of a dynamic shaft seal, power is transmitted through a magnetic field, helping to minimise leakage risk and improve containment on demanding duties.

AxFlow UK offers three ranges of mag drive gear pumps, covering both external gear and internal gear designs for chemical transfer, process dosing and general industrial fluid handling.

How mag drive gear pumps work

A magnetic drive pump uses a drive magnet connected to the motor shaft, which rotates an internal magnet connected to the pump’s rotating element—without the motor shaft passing through the pump casing. This removes the need for a dynamic shaft seal, creating a sealless pump design.

For gear pumps, the rotating element is a set of gears:

- External gear mag drive pumps: two meshing gears trap fluid in the tooth spaces and carry it from inlet to outlet, producing smooth, low-pulsation flow.

- Internal gear mag drive pumps: an inner rotor and outer idler gear move fluid through expanding/contracting cavities, typically offering good handling of a wider viscosity range and gentle transfer.

Because these are positive displacement pumps, flow is proportional to speed (until slip increases). Slip rises with lower viscosity and higher differential pressure—so sizing should consider actual operating viscosity and ∆P, not just water-like conditions.

Advantages of mag drive gear pumps

Mag drive pumps are best suited to duties where containment & reliability matter most, because the sealless design helps minimise leakage risk and provides isolation of the pumped fluid.

With gear pump hydraulics, you also gain:

- Accurate, repeatable flow for dosing/transfer (excellent speed control with VFDs)

- Stable discharge characteristics across varying backpressures (compared with centrifugal pumps)

- Low shear, low pulsation transfer (particularly on external gear designs)

When to use mag drive gear pumps

Mag drive pumps are commonly used when you really don’t want leakage—especially for corrosive and toxic liquids. They’re also well-suited to temperature extremes, where removing the dynamic seal can reduce leak risk and simplify containment.

Typical use cases for mag drive gear pumps include:

- Chemical transfer (acids, alkalis, solvents) where emissions control matters

- Dosing / metering skids where repeatable flow is required

- High-value fluids where product loss is costly

- Odorous or hazardous liquids where containment is a safety requirement

Key features and engineering considerations

1) Sealless containment (what “sealless” really means)

Mag drive gear pumps eliminate the dynamic shaft seal. That reduces leak paths, but the pumped liquid often lubricates internal bearings/bushes on many designs—so correct material selection and lubrication regime matter. For example, Pulsafeeder Eclipse notes it is lubricated by the process fluid and uses a seal-less leak free construction.

2) Positive displacement safety: always protect against deadhead

Gear pumps will keep generating pressure if the discharge is blocked. In any PD installation you should include overpressure protection (e.g., relief valve / bypass) sized for the maximum pump speed and worst-case viscosity.

3) Heat and temperature rise

Gear pumps can generate heat from viscous shear and internal recirculation. This is especially important on high viscosity duties and at elevated ∆P. Always validate:

- allowable temperature rise of the fluid

- vapour pressure margin at the inlet (avoid flashing/cavitation)

- magnet/can and bearing temperature limits

4) Solids handling and filtration

Gear pumps generally prefer clean liquids. If the process contains particulates, consider filtration/strainers (or alternative pump technology) to protect close clearances and bearings.

5) Viscosity range and “slip”

Performance is strongly affected by viscosity. Higher viscosity typically reduces slip and improves volumetric efficiency (up to the point where torque/temperature limits appear). Size the pump for your actual operating viscosity and temperature, not the datasheet headline.

AxFlow mag drive gear pump range

AxFlow supplies three mag drive gear pump ranges, covering small chemical duties through to higher flow industrial transfer.

Pulsafeeder Eclipse (external gear, mag drive)

A compact mag drive external gear pump range with strong chemical-transfer capability:

- Max capacity: 125 l/min

- Max differential pressure:3 bar

- Temperature range: -40 to 232 °C

- Max viscosity: 10,000 cP

- ATEX listed on the product page

Pulsafeeder Isochem (external gear, mag drive)

Higher flow/pressure capability for a wider set of process duties:

- Listed as mag drive external metal and plastic gear pumps

- Pressure up to: 14 bar

- Key specifications show flows up to:08 m³/h

Envirogear (internal gear, mag drive)

An internal gear mag drive option for thin to viscous products, positioned around reliability and seal-less containment:

- Listed as magnetically driven internal gear pumps

- Flows up to: 35 m³/h

- Pressure up to: 14 bar

- Temperature range: -20 to 93 °C

- Max viscosity: 11,000 cP

- Notes a single-fluid-chamber seal-less design and a between-the-bearing support system

Why buy mag drive gear pumps from AxFlow?

AxFlow offers one of the UK’s broadest mag drive pump portfolios and includes mag drive gear pumps within a wider sealless range—helping you select the right technology for containment-critical duties.

What you get:

- Application-led sizing (flow, ∆P, viscosity, temperature, NPSH margin)

- Material compatibility support (metals, plastics, lining options)

- Support for hazardous-area and compliance-driven installations (where applicable)

Quick sizing checklist (what we need from you)

To select a mag drive gear pump correctly, we typically need:

- Fluid name + concentration, temperature range, viscosity curve (or viscosity at operating temp)

- Required flow range (min/normal/max) and control method (fixed speed / VFD)

- Differential pressure range (including worst-case blocked filter / valve shut)

- Suction conditions (tank elevation, vapour pressure, inlet losses, available NPSH margin)

- Solids content / cleanliness level

- Any compliance requirements (e.g., ATEX, emissions/containment standards)