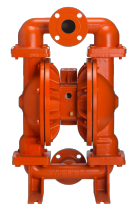

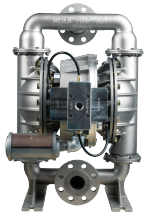

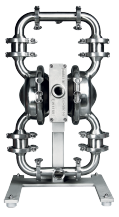

ATEX AODD Pumps

AxFlow offer both metal and plastic ATEX rated AODD pumps

ATEX AODD pumps (air-operated double diaphragm) are a popular choice for hazardous area fluid transfer because they are air-powered, positive displacement and typically sealless—ideal where flammable atmospheres may be present and leakage risk must be minimised. In ATEX zones, the pump must be specified so it cannot become an ignition source through static build-up, mechanical friction, impact sparks, or hot surfaces.

What “ATEX” means for AODD pump selection

ATEX compliance isn’t just a label—it’s about matching the pump and installation to the hazardous area classification:

- Zone (e.g., Zone 1 / Zone 2 for gas; Zone 21 / Zone 22 for dust)

- Equipment category (e.g., Group II, Category 2 or 3)

- Temperature class (T1–T6) / maximum surface temperature (especially important with viscous fluids or deadheading)

- Gas group / dust type (where applicable)

Because AODD pumps are pneumatically driven, there’s no electric motor on the pump itself—but ATEX still applies to the pump materials, the air valve assembly, and any ancillaries (solenoids, sensors, grounding hardware, and accessories) used in the hazardous area.

Why AODD pumps suit ATEX duties

AODD pumps are frequently specified for ATEX environments because they offer:

- No rotating shaft seal (reduced leak paths vs. many mechanically sealed pumps)

- Air-driven operation (simplifies electrical ignition risk on the pump)

- Safe stall on closed discharge (the pump typically stops cycling rather than overheating a motor)

- Good handling of aggressive chemicals and intermittently loaded services (common in chemical dosing/transfer)

Key ATEX engineering considerations for AODD pumps

To keep an ATEX installation compliant and reliable, these are the points that matter most:

1) Conductivity and static control

Static is one of the biggest real-world risks with diaphragm pumps. For flammable liquids and powders, you typically specify:

- Conductive pump construction (e.g., conductive plastics or metallic housings)

- Bonding/earthing provisions as part of installation

- Appropriate conductive elastomers where required by the duty

2) Temperature rise and “hot surface” risk

Even an air-driven pump can create heat through:

- high cycle rates

- viscous shear

- internal friction in the air valve

- deadheading against high backpressure

ATEX selection must consider worst-case operating conditions to stay within the required temperature class.

3) Chemical compatibility and containment

ATEX sites often handle solvents, hydrocarbons, and aggressive chemicals. Correct selection of:

- diaphragm material (PTFE, EPDM, FKM, etc.)

- valve balls/flaps and seats

- wetted-body material

…is essential for both safety and uptime. A compatibility mistake can look like an “ATEX problem” when it’s actually material degradation leading to leaks or performance loss.

4) Air supply quality and icing

Moist compressed air can cause valve icing in some conditions, which can interrupt operation. Filtration/drying and correct air plumbing help maintain stable cycling—important on critical transfer or dosing services.

ATEX AODD pumps from AxFlow

AxFlow UK supports hazardous-area projects by helping you specify an ATEX-rated AODD pump package that matches the zone classification, temperature class, fluid compatibility, and duty requirements—not just the flow rate. We can also support selection of the right conductive materials, earthing approach, and any accessories needed for safe operation in ATEX areas.

What we need to size and specify an ATEX AODD pump

For a correct and compliant selection, share:

- Zone / area classification (and any site standards)

- Fluid name, concentration, temperature, viscosity, and any solids

- Required flow range and discharge pressure

- Suction conditions (lift, inlet line size/length, tank details)

- Material preferences or restrictions (e.g., stainless vs conductive plastics)

- Any monitoring or containment requirements (leak detection, double diaphragm options)